Library Reference Number: 167

The Rise and Fall of the B24 Liberator

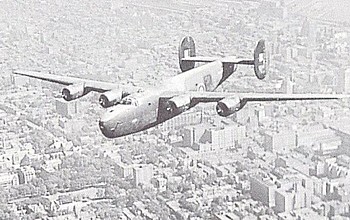

For those of us who flew in B24 Liberators and learned through experience to trust and cherish Consolidated's answer to the popular B17 Fortress, we can only regret the comparatively short life span of this aircraft. It was born out of sheer necessity. Before it's appearance, there was already a desperate need for an aircraft capable of greater payload and range. By example, the German U-boat menace was sinking thousands of tons of shipping in the mid-Atlantic area where air cover for convoys was absent. This came to be known as 'U-Boat Alley' and U-Boat Commanders later referred to this period as the 'happy times' and when the Allied forces lacked aircraft with adequate range. Germany, by contrast, entered the war with fourteen Condors and which had orginally been designed for use as transatlantic liners. In their new role, luxury seats were torn out to extend the range further and used to seek out convoys headed for the United Kingdom. The Condors were the eyes of the U-Boat fleet and were largely unchallenged during the early stages of the war. Convoy carriers, basically modified merchantmen with short decks installed and carrying the Seafire variant of the Spitfire did their part later in the war but it was long range aircraft like the B24 Liberators which rapidly began to the narrow 'U-Boat Alley' and helped concentrate the enemy into areas where they paid a heavy price with only one third of U-Boat crews surviving the conflict. It's just one area of war where the B24 Liberator earned a remarkable record in aviation history.

In the Middle and Far East, the Liberator proved to be a great asset in covering more air miles than previously by its designers. Distances were now being covered which were equivalent to an aircraft flying from the United Kingdom, crossong the Atlantic Ocean and back again without refuelling. From personal experience, I can recall when the Consolidated Aircraft Corp actually sent representatives to the Far East in 1945 to find out whether rumours of their aircraft flying twenty plus hours duration and covering over 3,000 miles range, were true. They were not easily convinced. Their verdict, I believe was one of suspicion and that refuelling points had been made available to enable the B24 to carry on flying such long range missions. This I can certainly deny, as one of my own longest operations in the Far East covered 3,600 miles with a flying time of 23 hours 25 minutes. More details about this particular flight can be found in this website library. (Library Index 093: Flying to Limits – Or Phantom Refuelling: Click Here to Go There). In any case, who in their right mind would consider the risks of landing to refuel in Japanese-held territory with especially with their reputation for gross atrocities towards prisoners? Given this harsh regime, how could such a logistical exercise have been carried out with any degree of relability?

In the Middle and Far East, the Liberator proved to be a great asset in covering more air miles than previously by its designers. Distances were now being covered which were equivalent to an aircraft flying from the United Kingdom, crossong the Atlantic Ocean and back again without refuelling. From personal experience, I can recall when the Consolidated Aircraft Corp actually sent representatives to the Far East in 1945 to find out whether rumours of their aircraft flying twenty plus hours duration and covering over 3,000 miles range, were true. They were not easily convinced. Their verdict, I believe was one of suspicion and that refuelling points had been made available to enable the B24 to carry on flying such long range missions. This I can certainly deny, as one of my own longest operations in the Far East covered 3,600 miles with a flying time of 23 hours 25 minutes. More details about this particular flight can be found in this website library. (Library Index 093: Flying to Limits – Or Phantom Refuelling: Click Here to Go There). In any case, who in their right mind would consider the risks of landing to refuel in Japanese-held territory with especially with their reputation for gross atrocities towards prisoners? Given this harsh regime, how could such a logistical exercise have been carried out with any degree of relability?

So where did the concept of the B24 Liberator take place, with its fuselage reminiscent of flying boat shape and the introduction of the high aspect ratio 'Davis Wing' and which had almost been rejected at birth by the Consolidated Aircraft bosses?

From a struggling beginning, the B24 rose to become the most vastly produced aircraft in the World War Two! By the end of the war, 19,256 B24s and B24 variants were produced, making it the most produced U.S. aircraft of the entire war. Today, less than 20 Liberators survive world-wide in varying stages of preservation.

It all began in the summer of 1937 when Reuben H. Fleet, president of Consolidated Aircraft met with David R. Davis, a freelance aeronautical engineer who had developed a wing design that was entirely different from any that had gone before. Perhaps for this reason, Fleet was not suitably impressed with the wing design as it had a long narrow chord, and a thick shoulder that Davis claimed gave much better performance than any other design. The Consolidated chief engineer I.M. Laddon was not initially impressed either, but had second thoughts that it might be worthy of a trial. After convincing his company president to at least agree to a test, this was carried out at the California Institute of Technology (now typically referred to as CalTech). Results of the wind tunnel trial were so unbelievably successful, that the wind tunnel instruments were recalibrated twice and in case mistakes had occurred with the readings.

With the growing possibility of America coming into the war, the U.S. Army asked Consolidated to become a production source for the B17 Flying Fortress but armed with the highly successful new Davis wing readings, it seems Consolidated had more ambitious plans in mind rather than merely following plans and drawings of an inferior design. They saw the possibilities and decided to proceed with a new design that would eventually become the B24 Liberator.

With the growing possibility of America coming into the war, the U.S. Army asked Consolidated to become a production source for the B17 Flying Fortress but armed with the highly successful new Davis wing readings, it seems Consolidated had more ambitious plans in mind rather than merely following plans and drawings of an inferior design. They saw the possibilities and decided to proceed with a new design that would eventually become the B24 Liberator.

During early January 1939, the Consolidated president asked designer Frank W. Fink to come into his office where he appointed him chief project engineer for a new design of aircraft. Fink was instructed to present a wooden mock-up of this new aircraft in two weeks and all this without drawings and resting on mere verbal descriptions on how it should look and incorporating the new Davis Wing, the twin tail of the Model 31, four engine nacelles from the PBY Catalina, and a new design fuselage containing two bomb bays, each as large as the single bomb bay of a B17 Fortress. The two week window was vital as the president and chief engineer were about to leave for Wright Field to arrange sale of the new bomber to the U.S. Army!

The wooden mock-up of the hastily devised new bomber, constructed without the usual initial drawings, was completed on time and the U.S. Army Board detailed to have a look at the model, recommended the Consolidated proposal to Washington in February 1939. A formal contract was signed and awarded on 30th March 1939, and work proceeded on the new aircraft; officially referred to as Model 32, to be completed by December 30th 1939. Amazingly, all this progress had taken place within a year and one cannot even use the term 'drawing board' as it had all started from an idea expressed verbally without a diagram of any kind.

The U.S. Army named the aircraft XB-24 and it made its maiden flight on 29th December 1939; just one day beneath the set deadline. By then, war in Europe was under way, and both British and French were seeking to catch up with their respective aircraft modernisation, particularly for a high-speed long-range bomber. The B24 Liberator had arrived on the scene at just the right moment in time. France ordered 175, the British 165, but before any new aircraft could be delivered, France had been compelled to surrender. The bulk of their order was taken over by Britain.

Initially, it seemed Britain had been caught napping in 1939 with the RAF still flying antiquated biplanes and apparently unwilling to move quickly to meet Germany's modern aircraft. By the summer of 1940, though, North American companies had collectively agreed to supply 26,000 aircraft with a delivery schedule of about one thousand per month. Don Bennett, a former President of the Aircrew Association, led the first batch of six Liberators to Prestwick on 14th May 1941. The flight took over fourteen hours.

Considering it's dubious start in life and when David R. Davis had initially been sent packing with his new controversial wing design, Consolidated's new aircraft was soon accepted as a resounding success. Among several other aircraft companies brought into cope with the huge demand, the Ford company at Willow Run was invited to participate. This led to Henry Ford's production chief, Charles Sorenson, visiting the Consolidated San Diego Plant in search of information. He stayed up all night planning automobile type assembly lines! He'd grown used to building cars with 15,000 parts whereas a B24 comprised 100,000 parts. Nevertheless, when Ford got moving, they eventually managed to produce a new plane at Willow Run every 53 minutes compared to San Diego's lesser rate of one plane per day. During its peak, Henry Ford employed 42,000 at Willow Run. Accommodation was even provided for hundreds of US Army Pilots to sleep in and at a state of instant readiness for new planes to be flown out quickly and in order to make room for others coming off the huge ever developing production lines.

Considering it's dubious start in life and when David R. Davis had initially been sent packing with his new controversial wing design, Consolidated's new aircraft was soon accepted as a resounding success. Among several other aircraft companies brought into cope with the huge demand, the Ford company at Willow Run was invited to participate. This led to Henry Ford's production chief, Charles Sorenson, visiting the Consolidated San Diego Plant in search of information. He stayed up all night planning automobile type assembly lines! He'd grown used to building cars with 15,000 parts whereas a B24 comprised 100,000 parts. Nevertheless, when Ford got moving, they eventually managed to produce a new plane at Willow Run every 53 minutes compared to San Diego's lesser rate of one plane per day. During its peak, Henry Ford employed 42,000 at Willow Run. Accommodation was even provided for hundreds of US Army Pilots to sleep in and at a state of instant readiness for new planes to be flown out quickly and in order to make room for others coming off the huge ever developing production lines.

My first flying encounter with a B24 took place at No.111 Operational Training Unit, Nassau where conversion from B25 Mitchells to Liberators and 'crewing up' took place. We then discovered what we had inherited from Mr Davis and the Consolidated designers: a flying machine with a 110ft wingspan and 66ft fuselage closely resembling a flying boat. Power came from four 1200 HP Pratt & Whitney Twin-Wasp engines with two banks of seven cylinders mounted on the Davis wing with No. 1 being the vertical one in rear bank; engines being borrowed from the Catalina PBY design and incorporating Stromberg pressure-injection carburettors. The elliptical tail fins had evolved from Consolidated flying boat design; Fowler flaps; Auxiliary Power Unit: Hydraulic pump on No.3 engine; Hydraulic Booster Pump cutting in to maintain pressure in two spherical accumulators to operate bomb doors for entry & brakes: Minneapolis Automatic Flight Control: Radar with 30-60-90 mile radius adjustment. Turbo Superchargers with exhaust bucket wheels. driving impellors to enable higher altitudes and added power for take-off. Being a Scot, it was a great source of pride to be told that the only place that could produce the superchargers and the metal bucket wheels capable of withstanding the abnormaly high temperatures, was John Brown's Shipyard in Glasgow!

Later on operational flying, I was to discover the joy of crouching up in the loft with a flickering torch and where the fuel transfer panel was situated. Engines could only operate with fuel from the main tanks, therefore additional fuel in auxiliary tanks in outer wings and bomb-bay had to be transferred at appropriate times. Transfer rate was seven gallons per minute, and as fuel consumption worked out at just under 1 mile to the gallon, in theory, every hour spent transferring fuel would buy an increase of 420 miles range. Another unusual feature was to negotiate the nine inch wide cat-walk running through the entire length of the bomb-bay which connected fore and aft sections of the aircraft. This had a tendency to develop a sense of balance since, with the bomb-doors open over a target, there was very little to hang on to and especially if pushing out additional supply packages.

Returning to life after flying training at Nassau, I was employed as a flight engineer at Montreal Airport, where along with American civilian pilots I air-tested all systems on newly arrived B24s prior to going into RAF service. On one occasion when walking out on the dispersal area looking for the specific Liberator I had been allocated to air-test, I noticed this plane, and which looked like a Liberator but only had a single fin and with an entry door on the side of the fuselage. Being extremely curious, I entered the aircraft only to discover the interior looked like Aladdin's Cave. Beautifully furnished with luxurious seating and lighting and fully equipped kitchen, I was standing trying to come to terms with this sight, when my admiration was halted by an airport security officer who demanded to know what I was doing there. His relief was much greater than mine after he examined my ID, as he had strict instructions that no person was to even approach Winston Churchill's private plane 'Commando'. Serial No. AL504 was a variation of a Liberator specially converted to transport the British Prime Minister on world-wide visits and war conferences.

This plane went missing with VIPs aboard between Azores and Ottawa on 26th March 1945!

While working at Dorval Airport, Montreal and air-testing new Liberators, I was totally unaware of Japan's atrocious record of barbaric treatment of prisoners, and decided to volunteer for operational flying in the Far East. Given a brand new Liberator I rejoined my Nassau crew and flew over the Atlantic to Prestwick, and then in short stages to India and eventually Ceylon, and where I joined 160 Squadron and where I completed over 500 hours on long-range operations. As such, I had virtually unlimited opportunities to put the B24 Liberator to the test and in all sorts of weather and during many long-range conditions perhaps never envisaged by its designers. Their initial stated range of 2,500 miles was often exceeded by a further one thousand miles in our attempts to drop agents and supplies over vast distances in Burma, Thailand and Malaya. I don't know what Consolidated designers would have thought if they had witnessed additional fuel tanks being fitted in the bomb-bays, with lengths of hose pipes connecting those tanks to booster pumps we had fitted on the cat-walk. A similar expression might have crossed their faces if they'd witnessed the child-type chute-slide we'd rigged up in the rear compartment to enable several guerrilla-type agents to slide down one-by-one out through the rear escape hatch over Japanese territory!

By the time VJ arrived in August 1945, I had found complete faith and confidence in the B24 Liberator. It had accomplished everything we had demanded of it and in very extreme circumstances. It never let us down and even when flying over the Indian Ocean in monsoon conditions, we ploughed through the violent turbulence, dropping many feet in an instant yet able to regain height soon after. Looking through the front windscreen, one could only see a solid wall of water with rain forcing its way through the seals of the mid-upper turret. Some critics have noted the B24 was not capable of being ditched without fatal results due to the roll-up bomb-doors collapsing on impact. Yet my second crew captain ditched in the Indian Ocean without loss of life. The only crew member seriously injured being the flight engineer, which is the reason I joined that crew to replace the injured member.

By the time VJ arrived in August 1945, I had found complete faith and confidence in the B24 Liberator. It had accomplished everything we had demanded of it and in very extreme circumstances. It never let us down and even when flying over the Indian Ocean in monsoon conditions, we ploughed through the violent turbulence, dropping many feet in an instant yet able to regain height soon after. Looking through the front windscreen, one could only see a solid wall of water with rain forcing its way through the seals of the mid-upper turret. Some critics have noted the B24 was not capable of being ditched without fatal results due to the roll-up bomb-doors collapsing on impact. Yet my second crew captain ditched in the Indian Ocean without loss of life. The only crew member seriously injured being the flight engineer, which is the reason I joined that crew to replace the injured member.

In the post war era and for some reason perhaps more related to marketing, the B17 Fortress seems to have attained gain greater credit and interest than the B24, but in addition to being faster and able to carry heavier loads than the B17, the B24 also proved more versatile. Its cavernous bomb-bays and box-like fuselage gave rise to alternate and post-war uses. Those ranged from ferrying gasoline and supplies over the Himalayas and supplying the 14th American Air Force, to being fitted with stretchers and bringing back those prisoners who had survived the horrors of the Japanese prison camps.

For me, this remains as an exceptional experience I shall never forget and witness what had been strong young men, turned into weak child-like skeletons and carry them back to a better future. The Japanese Forces, and who had ignored the Geneva Convention from the start, had carried out random acts of extreme torture encouraged by their superiors even to the point of bayonet practice on prisoners as a pastime. In my view, they'd sunk to the deepest depths of human depravity and violence; unworthy of any kind of respect!

Although the Royal Air Firce turned away from Liberators at the end of World War Two in preference to other new emerging aircraft designs; B24 Liberators continued in serviee until December 1968, and when the Indian Air Force officially retired its use of B24 Liberators. When the war ended, conditions of the Lend-Lease agreement with America stated that all American supplied aircraft should be scrapped or made unavailable to undesirable sources and which could damage the new envisaged period of peace.

A few Liberators returned to the UK, but the vast majority were deposited in the scrap yard at Chaken Airfield, Kanpur. The general understanding here was that they would be rendered un-airworthy, but in some cases, personnel did not have the heart to completely destroy aircraft which had proved so valuable to the Allied war effort. An Indian company which had a proven track record in adapting their skills to assembling and overhauling aircraft in times of need came to the rescue in repairing some of the less damaged aircraft, and restored them to a full condition of air worthiness. This was Hindustan Aeronautical Ltd, based in Bangalore, and who were so successful in perfecting a sterling job of returning several Liberators to first class flying condition, that six of the aircraft were the first of many to fly with No. 5 Squadron, Indian Air Force by 2nd November 1948. With regard to the Lend-Lease American/UK agreement, both countries were satisfied that this arrangement was no further threat to World Peace. It is estimated that 37 aircraft were resurrected in this manner.

It was a dramatic end to a plane where, in addition to its origins with the Consolidated Company in San Diego, one of the additional sites. Ford in Detroit, had built the largest bomber facility in the World at Willow Run stretching over one-mile long and employing 42,000 workers. In their heyday, Ford claimed they were producing a B24 aircraft every 58 minutes! Willow Run also had 1300 local beds for pilots on stand-by so that every plane could be flown off soon after completion.

As stated, the Indian Air Force retired their Liberators in 1968 and the Indian Government presented a few of their Liberators to UK, America and Canada as a goodwill gesture. The latter two countries collected their aircraft, but it was July 1974 before the UK Liberator (KN751) landed at Lyneham; first of all on display at Cosford, then subsequently moved to the RAF Museum, Hendon, and where it is presently on display. Once again, it was Hindustan Aeronautical Ltd, who displayed their first class professional skills in enabling Wing Cdr Doug Connor (ex-RCAF and No.160 Squadron) and Wing Cdr Chopra, IAF (retired), chief test pilot, to fly KN751 in stages back to the United Kingdom. This in itself was quite a feat, and provided a priceless asset to those who are aviation-minded and place value on the history of aviation and aircraft development.

Doug Connor and I had both been members of 160 Squadron based in Ceylon, and he contacted me after bringing Liberator KN751 back to UK in 1974, and asked me to come down to Cosford to see the aircraft. Doug had owned a private airfield in Ontario pre-war. This was converted to an EFTS within the Commonwealth Flying Training Scheme in Canada. Post-war, Doug had maintained his interest in aviation by entering the airline business and buying and restoring aircraft surplus to service requirements among other overseas business interests. In sporting circles, he was well known for his successes on the Cresta Run. Several items such as radio equipment and other components required upgrading before attempting the long flight to UK. According to RAF Museum Records, A/C Serial No. KN751, Doug Connor paid for the refurbishment of the aircraft. Doug also sent me a copy of a letter he sent to author Paul Gallico describing each stage of the flight back to UK. A brief extract from this document is contained in the Saltire Branch Web Library entitled “Recovering the Liberator.”

Thus ends a brief outline of the short life of a versatile aircraft which was almost rejected at birth because of its controversial new wing design, and was conceived by verbally expressed ideas without written drawings. It undoubtedly played a major role in reaching far into the Atlantic to combat the U-boat menace threatening life and shipping supplies to war-torn Britain. It also earned a warm place in the hearts of aircrew world-wide who had the operational experience to appreciate an aircraft which could do the job and get them back to base!

For further accounts relating to the B24 Liberator see:

CLICK HERE TO GO THERE - “Recovering the Liberator” – Branch Web Library Index Ref. 41.

CLICK HERE TO GO THERE - “Force 136 Liberators” – Branch Web Library Index Ref. 56.

CLICK HERE TO GO THERE - “Flying to Limits or Phantom Refuelling” - Branch Web Library Index Ref. 93.

CLICK HERE TO GO THERE - “45 (Atlantic Transport) Group, RAF” – Branch Web Library Index Ref. 120.

CLICK HERE TO GO THERE - “Tracking U862 via The Maldives” - Branch Web Library Index Ref. 163.